It consists of an open topped cylindrical steel shell equipped with a roof that floats on the surface of the stored liquid.

Floating roof tank design pressure.

Fixed roof this is a low pressure tank with a roof welded to the shell regardless of roof design or support methods.

Pressure for storage tanks is 15 psi and if the pressure is larger than this value it is considered as a pressure vessel.

Boil up is the sudden flashing of liquid water to steam.

Today controlled gas venting in to the atmosphere is becoming more and more important due to environmental regulations.

The roof rises and falls with the liquid level in the tank.

Implies the roof to float on liquid surface in the tank.

Floating roof storage tanks.

Floating roof tank allow the explosive gases in petroleum tanks to vent to atmosphere in a safe way.

As with the internal floating roof tanks the function of the fixed roof is not to act as a vapor barrier but to block the wind.

Double wall storage tank is a tank with an inner wall to contain a liquid as used in lng storage tanks it has an annulus space filled with insulation and an outer wall.

Floating roofs have been designed and used for more than a century.

2 floating roof tank.

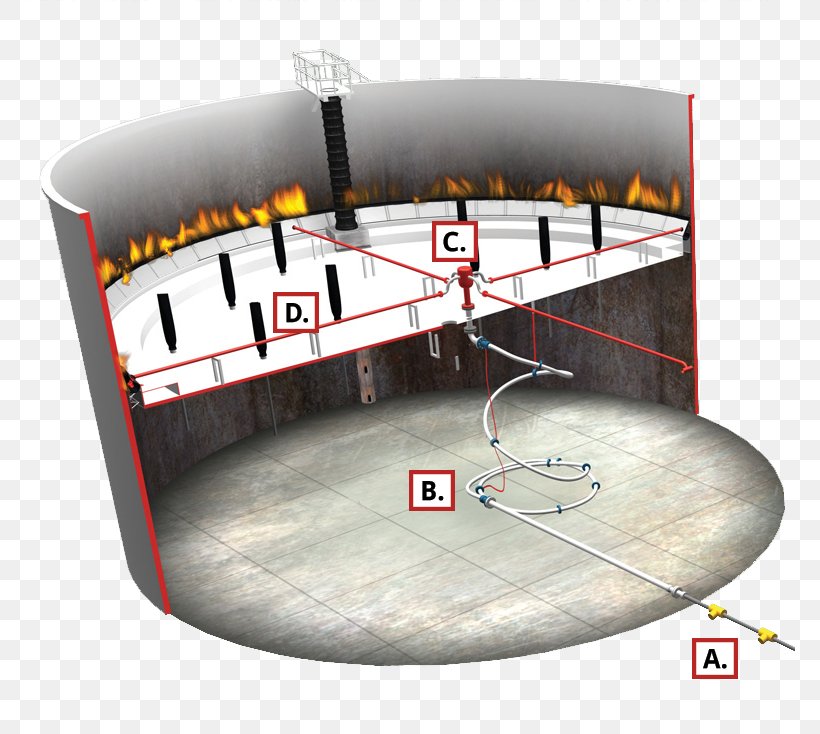

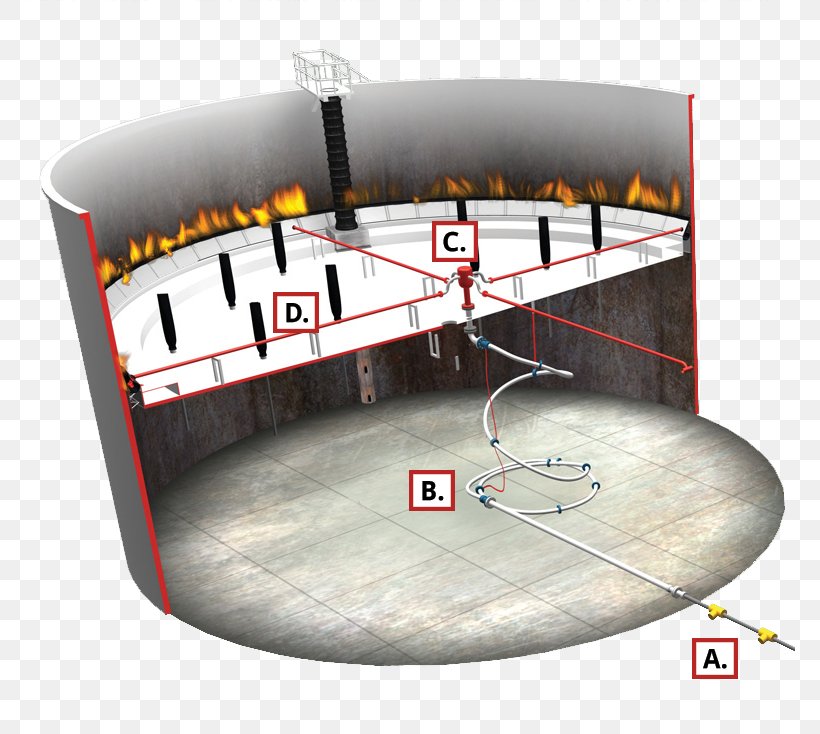

An external floating roof tank is a storage tank commonly used to store large quantities of petroleum products such as crude oil or condensate.