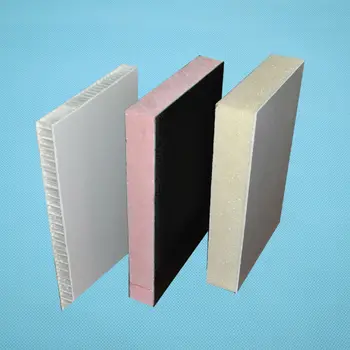

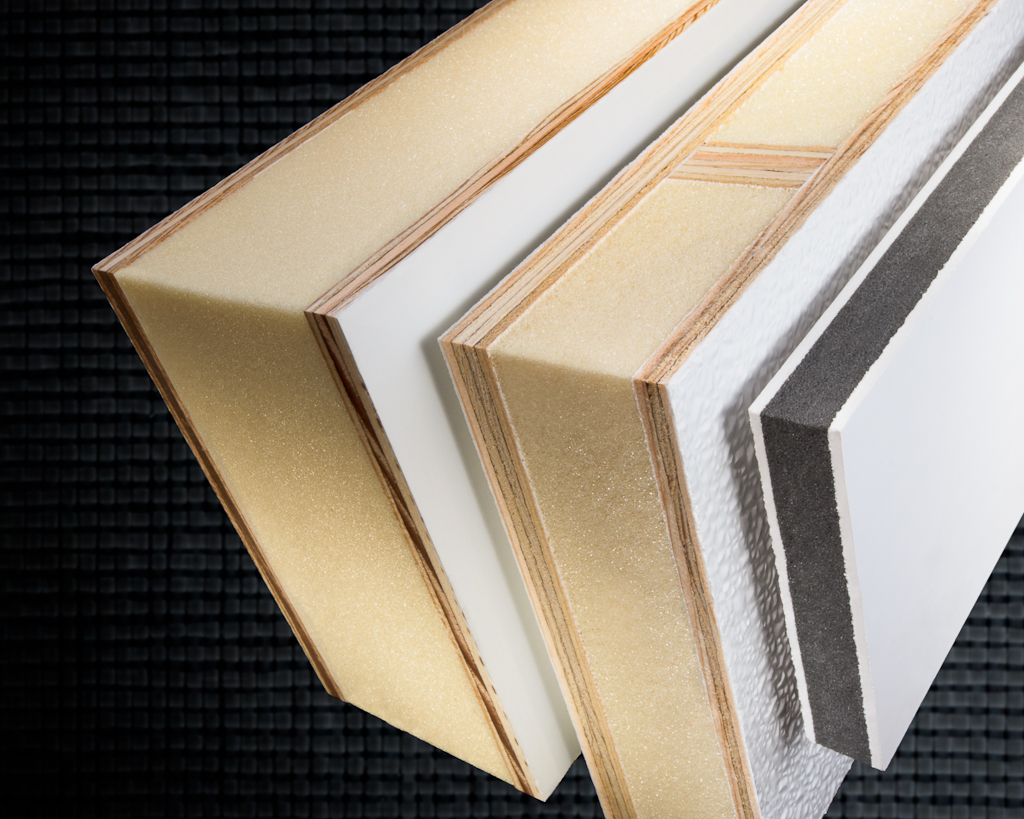

An advanced sandwich process allows the combination of different core materials with numerous skin options including fiberglass aluminum carbon fiber wood laminates and custom requirements composite panels are used in performance driven structures to reduce weight and increase strength.

Foam core fiberglass sheets.

Insulating boards are just one of the many types of foam insulation.

Corelite supplies high quality sandwich panels that are customized to meet different needs.

It is the true structural sandwich panel.

Acp composites fiberglass foam sandwich panels offer high strength to weight ratios tensile strength crush resistance max.

It is compatible with both polyester and epoxy resin systems.

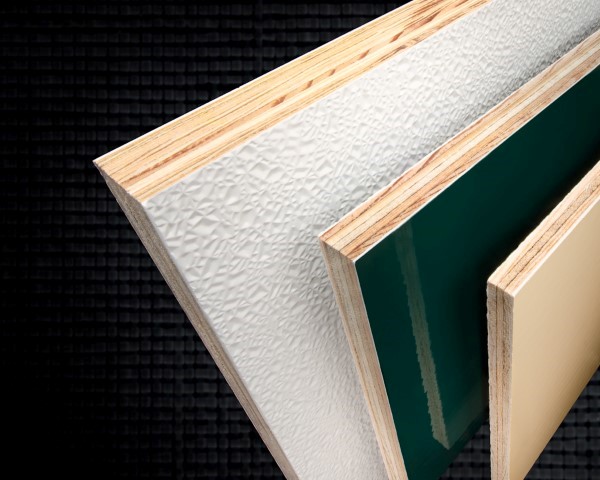

Polypropylene honeycomb core frp panels this plywood core fiberglass reinforced panel is the most popular structural frp panel used in the industry today.

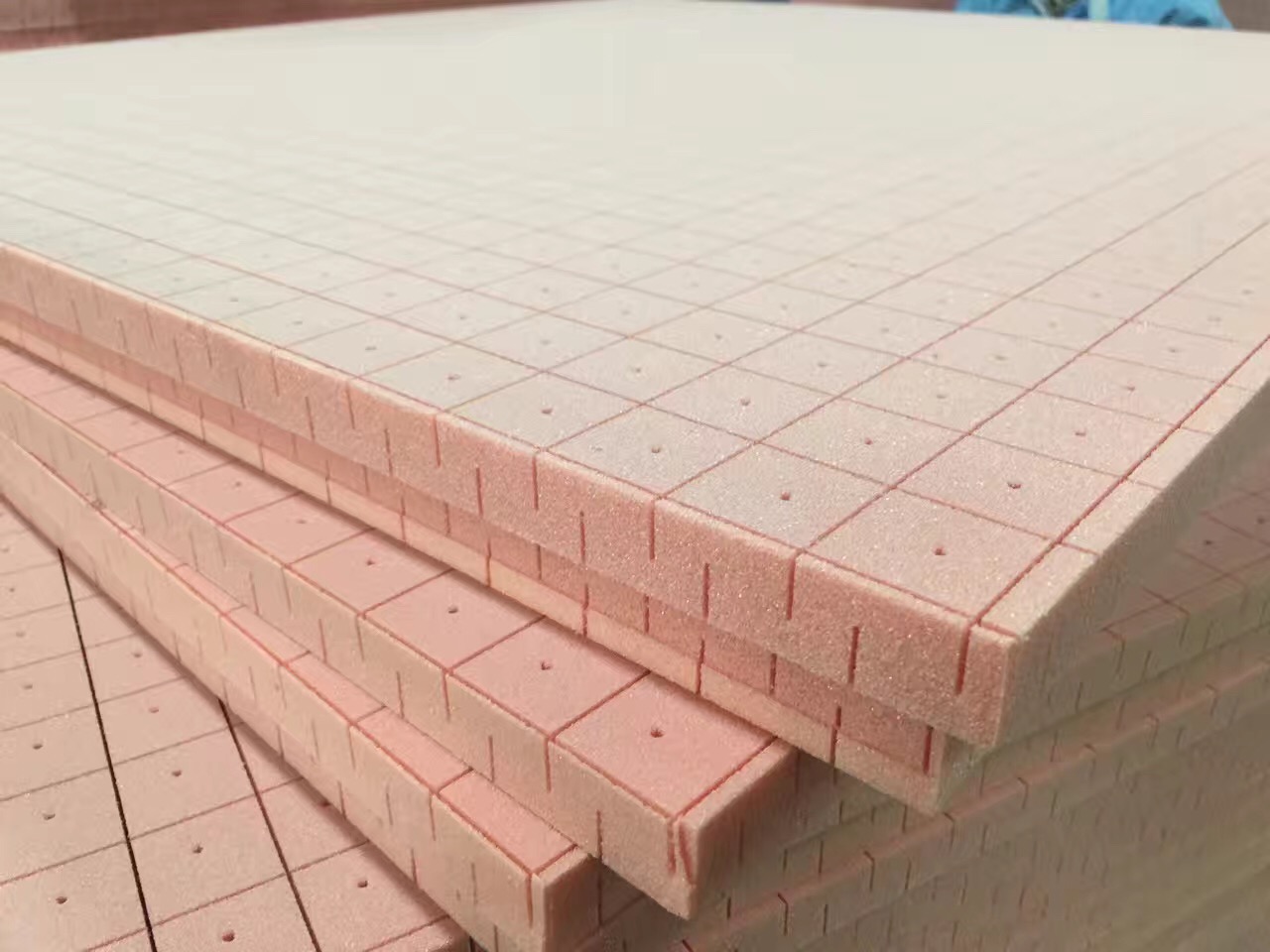

Core materials are a great way to stiffen a composite structure without adding a lot of weight.

Foam core composite panels this material is used to fabricate lightweight interior or exterior parts.

Stiffness and low density weight.

This eliminates thermal bridging which is the energy lost through wall studs.

Corrosion resistant panels have been successfully used in the pulp paper chemical mineral processing and power industries for 50 years.

Common skin materials are carbon fiber and fiberglass.

Cladfoam polyisocyanurate foam core structural panels.

A sandwich panel is a composite panel that uses stiff and strong skins face sheets bonded to a lightweight core.

This core has been at the heart of the marine industry for decades and is fairly inexpensive when a lower property cored laminate is needed.

We stock divinycell pvc foam balsa core coremat and marine grade plywoods for use in composite construction.

The no rot and light weight advantages of high density foam combined with the structural properties of fiberglass make coosa panels an excellent replacement for wood and other traditional core materials.

Common core materials are foam and aluminum or aramid honeycomb.

Scored sheets with scrim able to conform to curved surfaces.

The panels provide a continuous energy efficient surface.

This sheet foam is a rigid closed cell material with excellent thermal insulation and flotation properties.

Great for hulls and decks.

The studs conduct more heat than the insulation between them.

Coosa composites manufactures structural panels made of high density polyurethane foam reinforced with layers of fiberglass.

.jpg)